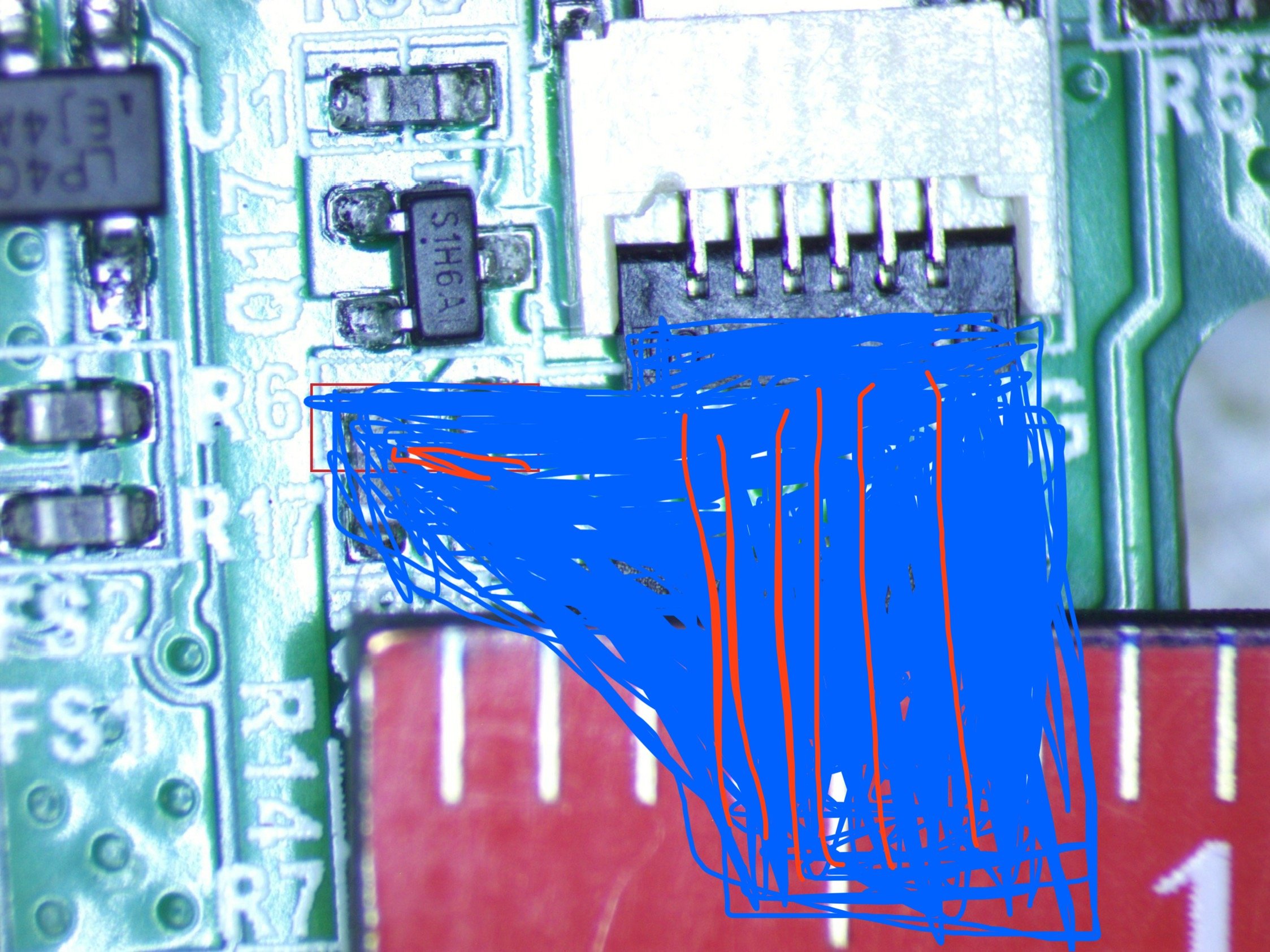

I’m working on a mod kit for a popular item, but my target audience isn’t likely to have a soldering iron. The majority of the project connects to an exposed ribbon connector, but I need to short two terminals to force a power supply on.

Any ideas on a method I could provide for people who can’t solder? Maybe a strip of copper tape?

Any metallic conductive epoxies out there. JB Weld or such

Only need a very tiny well placed drop

A thin wire attached to some tape placed perfectly to short them?

Design a plastic housing for the connector that puts pressure on short while the ribbon is plugged in. Put a short in the plastic housing.

Making some assumptions here but…

If i didn’t have a soldering iron, I’d probably grab a diode or resistor leg, snip it just enough to bridge the gap, press it down on the contacts, use super glue to hold it in place on both sides and the middle until it held and hope the glue doesn’t block the contacts.

But this is an extremely shoddy solution and i doubt it will last long. You have to hold it firmly in place or the glue will get underneath the component leg. The user can’t let it roll around under the finger. I suggest pressing it against the upper side of the contacts in the picture for leverage. Try it out yourself and see if you can do it. Once you verify with a multimeter you get current through, you can apply more super glue on top between the contacts to give it a little more grip, that may make it hold on for longer. Since it’s for a low current application I’m betting just the contact surface of the component leg with the solder blobs underneath will be enough and will not overheat, but i would suggest letting it run a bit just to make sure. You can always make it just a smidge longer in order for the component leg to wrap around the blobs to increase the contact surface, in sort of a C shape.

A soldering iron for students can be pretty cheap and I’m only suggesting this alternative so you have some sort of low cost solution that doesn’t involve one. Any diode or resistor will do, really, for like 5 cents and superglue for like 2/3€. Or if you want to put it in a kit just send small snips of tin plated, copper clad steel wire, but depending on how many kits you are manufacturing, it might be more cost effective just to use resistor/diode legs harvested from stuff you’ve got lying around.

You can get conductive adhesives but it would probably be cheaper to just include a soldering iron in the kit… I’m not sure I would be confident in getting good contact with self adhesive metal tape, your best option there is to probably get a small amount and experiment.

Imo if your audience does know how to properly short two things, or solder then you’re targeting the wrong audience or they need to learn some basic skills. Disclaimer everything but someone will blame you regardless

Everyone needs to start somewhere. The goal of this project is for an everyman to repurpose some e-waste. Hoping to maybe inspire a few people to learn more.

Fuck yeah mam. As someone who has zero formal education but also zero fear of learning to do something that needs to be done/fixed/upgraded I applaud you. There are too many people like the comment you respond to that have what I call the shitty better than you can understand attitude. I see it asking what abbreviations mean and get this type of response all the time “if you don’t know what ACKSNTJENSNFBF means than youre in over your head and should just quit now” 👍🏿 cool except 45 mins of googling later and I understand what it meant and that it took that person longer to write the condescending response than it would’ve took to explain it. So good on you for giving a fuck to help educate regardless of audience experience.

Hold a small piece of metal (paper clip?) between solder pads with a tweezer. Heat up tip of a metal fork/spoon (Sharp edge of fork could work better) on a stove. Take it from stove and use it immediately to melt the solder on one pad (seems like there is already enough solder there). I am not sure if it would work but maybe worth trying. Heating entire fork could be hard, so maybe something with smaller metal mass could work better, like a screwdriver, nail clipper etc).

They’ve asked for a good method for a non-technical person, not a bad one for a freaking MacGyver.